Problem:

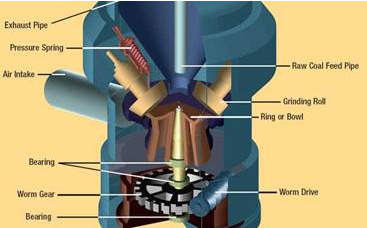

A Midwestern USA Power Company requested STI offer a solution for continuous vibration monitoring of their 6 Coal Pulverizers. They required that the vibration values be digitized and sent to their Plant DCS/Historian for monitoring and trending. They had purchased a wireless system from a competing company but the system was failing due to communication errors. 10 each 100 mv/g Accelerometers were to be monitored on each Coal Pulverizer with some being embedded within the Pulverizer. Slow speed shafts complicated the solution. The Coal Pulverizers were mounted indoors and the user wanted a wireless solution as they did not want the cost or complexity of installing conduit and wire.

Solution:

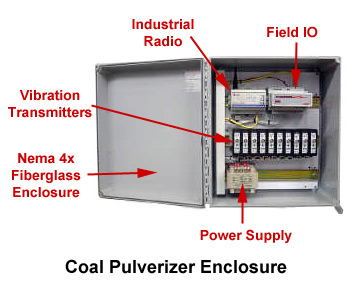

STI offered a local to the machine mounted solution comprised of a CMCP500 Fiberglass Enclosure, CMCP530 Velocity Transmitters, CMCP590 Acceleration Enveloping (gE) Transmitters, CMCP515 Power Supply, Local Field IO and Ethernet Industrial Radio using Modbus TCP/IP. An independent system was mounted at each Coal Pulverizer with all units communicating to a Master Radio connected to the Plant Historian via Cat5e cable.

The 2.4 GHz, Spread Spectrum, Frequency Hopping, 128 bit encrypted, Industrial Radios offered by STI use standard IEEE 802.3 Ethernet Protocols and have proven to be extremely reliable and durable in multiple installations worldwide.

CMCP590 Acceleration Enveloping Transmitters were used on the slow speed (<60 RPM) shaft bearings. Enveloping has proven to be a excellent parameter for monitoring on slow speed bearing where other parameters are not technically feasible. For further information on Acceleration Enveloping please see STI's Application Note, ENV Acceleration Enveloping.

Eight (8) Accelerometers were mounted including two on the motor bearings, two on the worm screw bearings, one on the bearing at bottom of bull gear grinding roll and one on each of the three grinding roll assemblies.

A. Coal Pulverizer System:

Each Individual Coal Pulverizers system was mounted locally to the machine to keep Accelerometer wiring short, maximizing signal and minimizing noise. Transmitter based the system is easy for plant personnel to troubleshoot and maintain.

B. Master Radio:

Master Radio was mounted at end of Coal Pulverizer building with easy access via Cat5e cable to the Plant DCS/Historian. The System was programmed, integrated and tested at STI prior to shipment and began working immediately on installation.

Results:

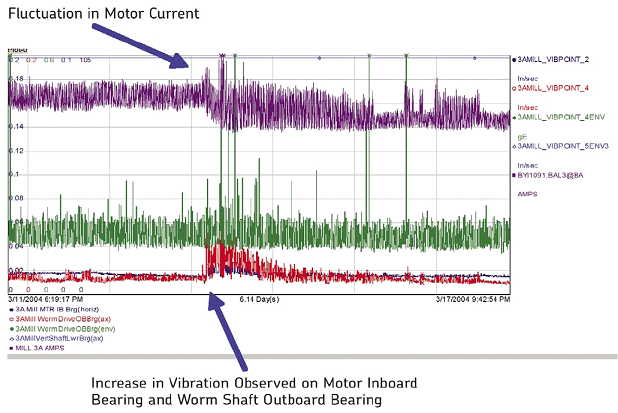

Within a short period of time after installation a machine "Save" was credited to the system for identifying a failing bearing prior to catastrophic damage. As the vibration values could be viewed in the plant historian they were confirmed by fluctuations in motor current, as shown below. As a result the system was installed at a sister power plant along with being expanded to Balance of Plant including FD, ID and PA Fans.

For help solving your machinery monitoring problems please feel free to contact STI. We are available to answer questions and your ideas and comments are appreciated.

|